OSHA Footwear Compliance Checker

Determine if Your Footwear Complies with OSHA Standards

Select the hazards present in your workplace to see if Crocs meet OSHA requirements.

Check all hazards present in your work environment

What This Tool Shows

- Based on your workplace hazards, we'll determine if Crocs meet OSHA standards

- Crocs may be acceptable in low-risk environments but not in high-risk settings

- OSHA requires footwear to match specific hazards, not specific brands

- When Crocs fail, we'll suggest compliant alternatives

Select workplace hazards to see if your Crocs are OSHA-compliant.

When you wonder if slipping into a pair of Crocs (lightweight, slip‑on foam clogs) breaks OSHA (the U.S. Occupational Safety and Health Administration) rules, the short answer is: it depends on the job, the hazards, and the employer’s safety program. Below you’ll find a step‑by‑step breakdown of what the law actually says, where Crocs are acceptable, and when they become a clear violation.

Key Takeaways

- OSHA does not ban Crocs outright; it requires OSHA footwear regulations to match the hazards of the worksite.

- In low‑risk environments (e.g., office, retail) Crocs often meet the standard if they have slip resistance and a closed toe.

- Construction, manufacturing, labs, and any area with heavy objects, puncture risks, or electrical exposure demand ASTM‑approved protective shoes.

- Employers must document a footwear policy in their safety plan and enforce it during inspections.

- If a worker is injured because the footwear did not meet the required protection, the employer can face citations and workers’ compensation claims.

Understanding OSHA’s Footwear Requirements

OSHA’s rule on protective footwear lives in 29CFR1910.136. The core points are:

- Employers must assess workplace hazards and select footwear that protects against identified risks.

- The chosen shoes must meet the ASTMF2413‑18 test standards for impact, compression, puncture, electrical, and slip resistance.

- When a specific hazard exists (e.g., falling objects), a “hard‑toed” shoe is mandatory.

OSHA does not list brands; it focuses on performance. That means any shoe-Crocs, steel‑toe boots, or slip‑resistant sneakers-can be compliant if it passes the right tests.

When Crocs Might Pass an OSHA Inspection

In many low‑hazard settings, a pair of Crocs can satisfy the rule, provided they have these features:

- Closed‑toe design (most Crocs models meet this).

- Slip‑resistant outsole (the “LiteRide” and “Classic Clog” lines earned a slip‑resistance rating under ASTM F2913‑19).

- No exposed metal parts that could conduct electricity.

For example, a customer‑service rep in a call center, a bartender in a dry‑clean bar, or a librarian moving books on carpeted floors can often wear Crocs without breaching OSHA standards. The key is that the employer has documented the hazard assessment and concluded that the risk of foot injury is low.

High‑Risk Settings Where Crocs Fail the Test

In environments where the stakes are higher, Crocs usually fall short. Here are the most common hazard categories:

| Hazard | Required Protection | Typical Crocs Rating | OSHA Verdict |

|---|---|---|---|

| Falling or rolling objects (construction, warehouse) | Impact & compression (e.g., steel toe, composite toe) | None | Violation |

| Puncture hazards (nails, metal shards) | Puncture‑resistant sole | Not puncture‑tested | Violation |

| Electrical work (live circuits) | Electrical hazard rating (EH or HRC) | No rating | Violation |

| Oil/grease‑slick floors (food processing, automotive) | Slip‑resistance rating (ASTMF2913) | Limited slip rating | May be OK if slip test passed, but many sites require higher rating. |

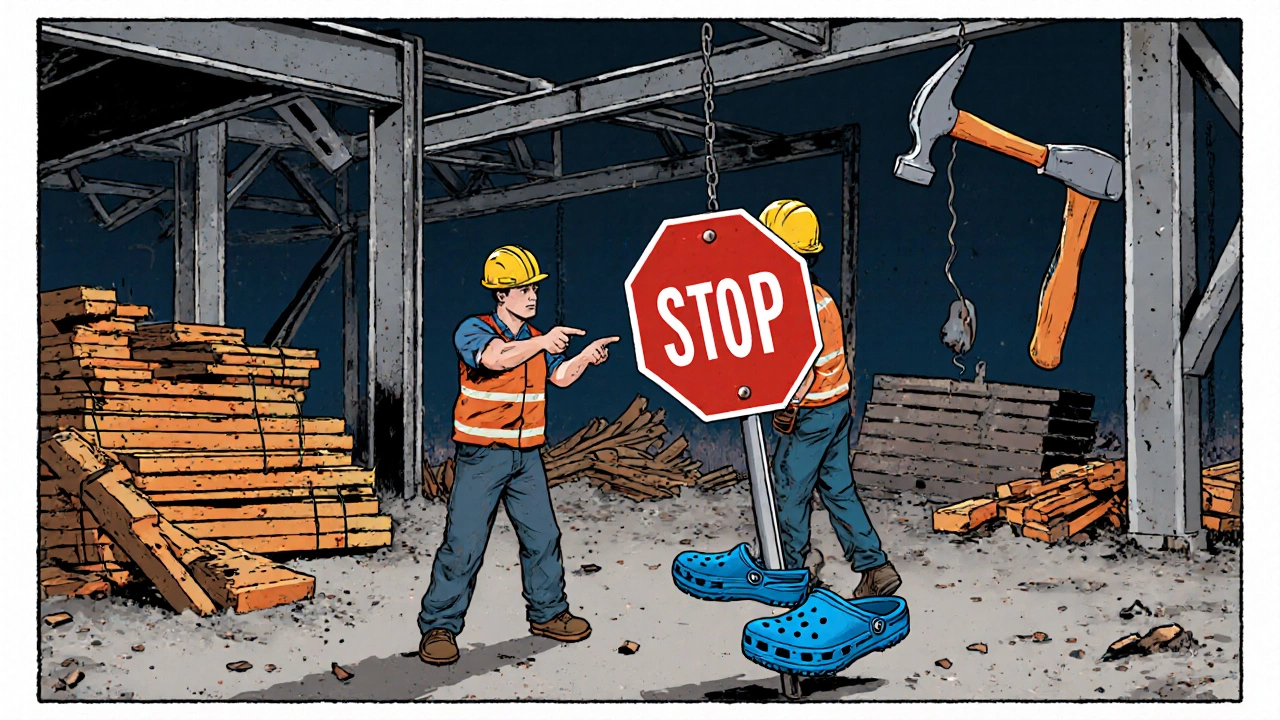

In the construction trades, for instance, the Construction Industry safety plan will list a “hard‑toe, puncture‑proof” requirement. If a worker shows up in Crocs, the site safety officer can issue a “stop work” order and call in OSHA for a formal citation.

How Employers Should Handle Footwear Policies

A solid workplace safety program includes a written footwear policy that ties directly to the hazard assessment. The policy typically covers:

- Hazard analysis: Identify slip, impact, puncture, and electrical risks for each job function.

- Footwear specifications: List required ASTM ratings (e.g., “ASTMF2413‑18, rating I/75 for impact”).

- Approved brands/models: Employers can name specific approved shoes, but they must also allow equivalents that meet the same test standards.

- Enforcement: Routine inspections, “shoe checks” at shift start, and disciplinary steps for non‑compliance.

If an employee is injured while wearing non‑approved footwear, OSHA can issue a citation for “failure to provide and enforce adequate personal protective equipment (PPE).” The employer may also face higher workers’ compensation costs because the injury could be deemed preventable.

Alternative Footwear Options That Meet OSHA Standards

When Crocs aren’t up to the job, there are plenty of affordable alternatives that pass ASTM testing:

- Composite‑toe shoes: Lighter than steel, still meet impact requirements.

- Slip‑resistant sneakers: Many brands now carry ASTM‑F2913‑rated outsoles.

- Puncture‑proof work boots: Steel or Kevlar plates in the sole add protection for construction sites.

- Electrical‑hazard (EH) rated footwear: Designed for electricians, often marked with “EH” on the side.

Most of these options cost under $80 and can be purchased in bulk for a company‑wide rollout. Adding a simple “footwear compliance” checklist to the onboarding packet can save a lot of hassle later.

Practical Checklist for Workers and Managers

Use this quick cheat‑sheet the next time you’re unsure about shoe compliance:

- Identify the primary hazards of your task (impact, puncture, slip, electricity).

- Match the hazard to the required ASTM rating (e.g., I/75, P/45, EH).

- Check the shoe’s label or manufacturer’s spec sheet for that rating.

- If the shoe is unlabeled, treat it as non‑compliant and choose an approved alternative.

- Document your choice in the safety log and keep a photo of the shoe’s tag.

Following these steps keeps you safe, keeps your employer out of trouble, and makes OSHA inspections a breeze.

Frequently Asked Questions

Does OSHA have a specific rule that bans Crocs?

No. OSHA’s rule focuses on performance standards, not brand names. If Crocs meet the required ASTM tests for the hazards present, they are allowed.

Can I wear Crocs in a hospital?

Many hospitals allow Crocs that have slip‑resistant soles and a closed toe, but they often require a chemical‑resistant coating. Always check the facility’s PPE policy.

What happens if I get injured while wearing non‑compliant shoes?

The injury may be deemed preventable. OSHA can cite the employer for failing to provide proper PPE, and workers’ compensation may be reduced or denied.

Are there any Crocs models that meet ASTM slip‑resistance standards?

Yes. The Crocs Classic Clog and LiteRide series have been tested under ASTMF2913‑19 and earned a slip‑resistance rating suitable for many low‑hazard workplaces.

How often does OSHA inspect footwear compliance?

Footwear is usually reviewed during a general safety inspection or when a foot‑related injury is reported. Inspectors focus on whether the employer’s written policy matches the actual shoes being worn.