Footwear Safety Assessment Tool

Footwear Safety Assessment

Answer these questions about your workplace to determine whether you need safety shoes or work shoes.

Recommended Footwear

Important: Always check your employer's risk assessment and local regulations before purchasing. Safety standards vary by region.

When you hear safety shoes are footwear designed to protect the wearer from workplace hazards such as falling objects, punctures, slips and electrical shocks, you probably picture a heavy‑duty boot with a steel toe. But not every job demands that level of protection, and not every shoe labelled “work shoe” offers the same safety features.

In this guide we’ll break down what each type of shoe actually does, where the overlap ends, and how to pick the right pair for your daily grind. By the end you’ll know whether you need a certified safety shoe, a sturdy work shoe, or maybe both.

Key Takeaways

- Safety shoes meet specific standards (ISO20345, ANSI/ISEA107) and provide toe, slip, and electrical protection.

- Work shoes are durable everyday boots or sneakers that may lack formal safety ratings.

- Choose based on the hazards you face: falling objects, chemicals, static, or just long‑hour comfort.

- Proper fit, break‑in period, and regular maintenance extend the life of both shoe types.

- When in doubt, check your employer’s risk assessment or local regulations.

What Are Safety Shoes?

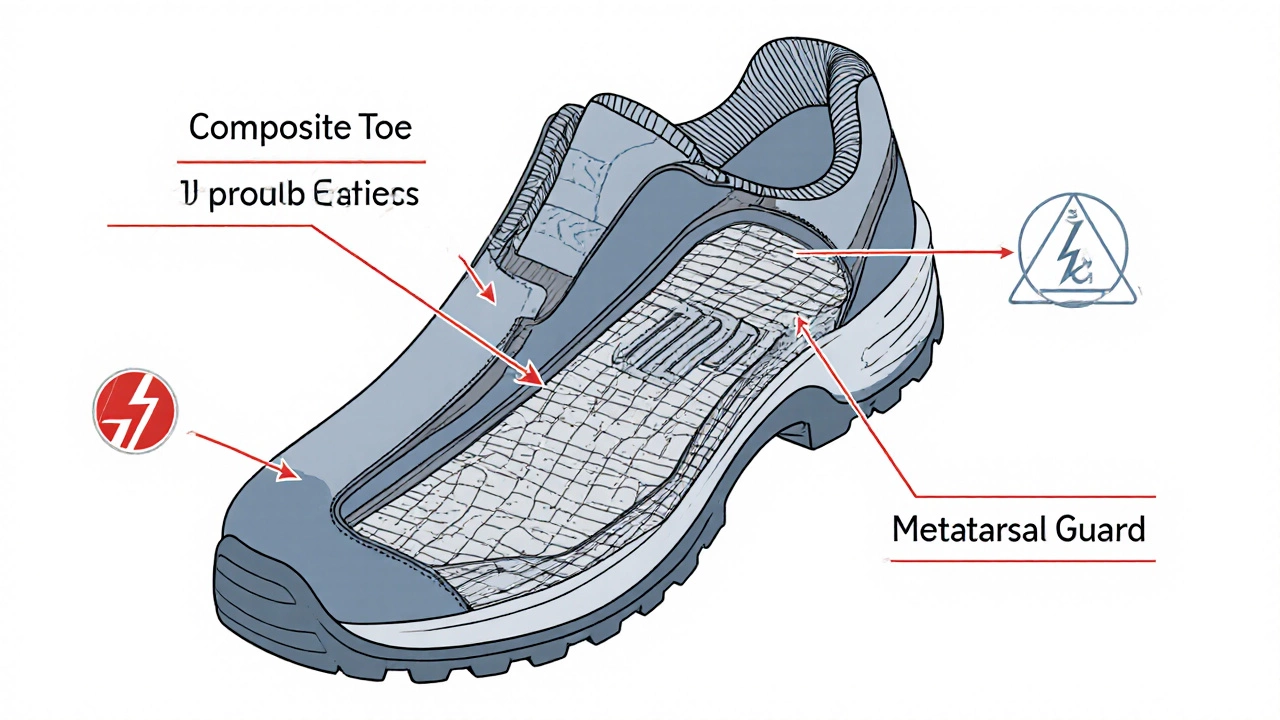

Safety shoes are footwear that has been tested and certified to protect against defined workplace risks. They typically feature one or more of the following built‑in guards:

- Toe protection - steel, aluminum, or composite caps that can absorb impacts up to 200J.

- Slip resistance - outsole designs meeting the ISO20345 slip‑resistance test, often indicated by a slip‑resistance rating of “SRA” or “SRB”.

- Electrical hazard rating - classified as “EH” for low‑voltage protection (up to 600V).

- Metatarsal guard - a secondary shield that covers the foot’s upper arch.

The standards behind these claims matter. In Europe, ISO20345 requires a minimum 200J impact test and a 15kN compression test for toe caps. In the U.S., ANSI/ISEA107 defines four protection levels (Class I-IV) that cover impact, compression, puncture, and electrical hazards.

What Are Work Shoes?

Work shoes are durable shoes intended for manual or industrial tasks but without formal safety certification. They focus on comfort, traction, and basic durability. A typical work shoe might have a reinforced toe box, oil‑resistant soles, and a breathable lining, but it won’t carry the stamp of compliance that safety shoes do.

Because they lack a mandatory testing regime, work shoes can vary wildly in quality. Some brands market “work‑grade” sneakers that meet occupational comfort standards (e.g., EN ISO 20344 for ergonomics), while others are simple leather boots meant for light tasks.

Side‑by‑Side Comparison

| Feature | Safety Shoes | Work Shoes |

|---|---|---|

| Toe Protection | Steel, aluminum or composite toe (200J impact) | Reinforced toe box, no certified impact test |

| Slip Resistance | Meets ISO20345 slip‑resistance rating (SRA/SRB) | General tread design, no formal rating |

| Electrical Hazard | EH rating (up to 600V) or E‑rated sole | Usually none unless explicitly stated |

| Standards | ISO20345, ANSI/ISEA107, ENISO20344 (optional) | No mandatory standard; may follow comfort guidelines |

| Typical Industries | Construction, manufacturing, oil & gas, electrical | Warehouse, light‑maintenance, hospitality |

| Price Range (NZD) | 120-300 per pair | 60-150 per pair |

How to Choose the Right Pair

Start with a simple question: What hazards does your job expose you to? If you handle heavy pallets, work near scaffolding, or have any risk of falling objects, you need a certified safety shoe with toe protection. If your role involves a lot of walking on wet surfaces but no impact risk, a slip‑resistant work shoe might be enough.

- Impact & Compression - Look for “200J” or “steel toe”.

- Electrical - Choose shoes marked “EH” or “E‑rated”.

- Puncture Resistance - Some safety shoes include a puncture‑proof midsole; useful in construction or recycling.

- Comfort & Fit - Break‑in time matters. Look for breathable linings, shock‑absorbing midsoles, and a proper width.

- Environment - Oil‑resistant soles for mechanics, waterproof membranes for outdoor work.

Don’t forget local regulations. NewZealand’s Health and Safety at Work Act requires employers to provide footwear that meets the relevant risk assessment, often referencing either the ISO or AS/NZS standards.

Maintenance Tips to Keep Your Shoes Safe

Even the toughest safety shoe can lose its protective qualities if you neglect it. Follow these simple steps:

- Clean off mud and chemicals after each shift with a damp cloth.

- Air‑dry shoes away from direct heat; ovens or radiators can warp toe caps.

- Inspect the toe cap and sole weekly for cracks, worn‑down tread, or delamination.

- Replace insoles regularly to maintain foot support and reduce fatigue.

- Store shoes on a rack or in a breathable bag to prevent mold.

When any protective component shows signs of wear, replace the whole shoe-not just the sole-because the certification is only valid for an intact unit.

Common Misconceptions

Many workers assume that any “hard‑boot” qualifies as a safety shoe. In reality, only footwear that carries an official certification label (ISO20345, ANSI/ISEA107) guarantees the tested performance. Another myth is that composite toe caps are weaker-on the contrary, they can be lighter and just as impact‑resistant as steel, while offering better slip resistance because they don’t conduct heat.

Frequently Asked Questions

Do safety shoes need to be replaced more often than work shoes?

Yes. Because safety shoes undergo rigorous impact and compression tests, the protective parts wear out faster. Most manufacturers recommend a 12‑month replacement cycle for high‑risk environments, whereas work shoes can last 18‑24 months if the sole remains intact.

Can I wear safety shoes for casual use?

You can, but they’re heavier and less breathable than regular sneakers, so you’ll likely feel uncomfortable on a day off. If you need occasional protection, consider a lighter composite‑toe model.

What does the ‘SRA’ marking mean?

‘SRA’ indicates a slip‑resistance test on a smooth ceramic tile with a 1mm water film. It’s the most demanding slip test in the ISO20345 series, ideal for wet or oily floors.

Are composite toe shoes safe for electricians?

Yes, as long as they carry an EH (Electrical Hazard) rating. Composite materials are non‑conductive, which actually makes them a good choice for electrical work.

How do I verify that my shoes meet ISO20345?

Look for the CE mark and a label that lists “ISO20345:2016” (or newer). Reputable brands also provide a test certificate on request.